Dunnage (Dry Cargo)

- Marine Teacher

- May 21, 2020

- 7 min read

DUNNAGE

Dunnage is used for general/breakbulk cargo, so as to spread the weight uniformly, for enabling lashing to be taken and preventing any damage to cargo due to ship sweat or unintentional waterlogging.

types and sizes of material used for dunnage.

Dunnage is the name used for all materials which are not firmly attached to the cargo transport unit, the cargo or its packaging, and are used to protect the goods and their packaging from moisture, contamination, and mechanical damage. It includes - wooden dunnage, beams, planks, boards, wedges, plywood and hardboards, walking boards, mats, paper, sailcloth, canvas, and tarpaulins; plastic and metal sheets, spray covers; cardboard and paperboard, packing paper, oiled paper and fabric paper, talcum powder, etc.

The main functions of dunnage are:

Protection against sweat and condensation water

Protection against moisture and liquids

Protection against soiling and contamination

Protection against mechanical damage

The nature of the materials used must ensure that the packages or the cargo transport unit are adequately protected. The materials themselves must not be wet, moist, odor-tainted, or contaminated. The quality of the material must be determined for each individual case by assessing the value and susceptibility to damage of the load, the means of transport, the intended protection, and other similar factors. The special properties of the particular type of dunnage used must be taken into account. Wooden dunnage made of squared lumber, planks, boards, roof bows, slats, and battens, are very suitable for distributing pressure, bridging or lining cavities and gaps, creating air channels and enhancing friction. Since wood can be infested by pests, only wood that has been impregnated against insects or fumigated may be used on certain trade routes.

Wooden boards, wooden panels, walking boards, chipboard, and hardboards are very suitable for distributing pressure and have a high loading capacity provided they are sufficiently thick. Since water-repellent, pest-proof, or fire-retarding wood is odor-tainted as a result of such treatment or could have other harmful effects, it must virtually never be used with foodstuffs or similar items. Mats made of bamboo, reed, etc. only protect against surface dirt, not against dust. They absorb moisture and under certain circumstances release it back into the atmosphere. This can protect adjacent loads. Mats are easy to put in place and roll back up again and do not cause any significant loss of stowage space. Canvas has a water-repellent impregnation and therefore not suitable for odor-sensitive goods. They are dust-tight. They impede air circulation.

Tarpaulins are watertight, dust-tight and airtight and very expensive. They must be handled with care if long life is to be expected. It is very rare that tarpaulins will not be needed as a cover to protect against moisture and similar influences. Jute coverings, also known as "wrappers", protect against surface dirt but not dust. They are breathable and allow a minimal amount of ventilation. They pass on absorbed moisture to the wrapped or surrounding cargo items.

Sailcloth has similar properties to the canvas. Plastic sheeting is available in a number of different thicknesses. It is neutral in odor, inexpensive, and generally acid-proof and alkali-proof. It is watertight, dust-tight, and airtight but only impervious to water vapor to a limited degree. It has a low loading capacity if it is not sufficiently thick. Composite sheeting is often very heavy-duty but comparatively expensive. Paper, e.g. normal kraft paper, is inexpensive and dust-tight, but very sensitive to moisture. Fabric paper has a higher strength. Oiled paper is watertight. Tissue paper is acid-free. Dispersible material such as talcum powder and similar materials can be used to prevent cargoes from "caking" together. Depending on their use and application, a distinction is made between:

Floor dunnage

Interlayer dunnage

Top dunnage

Side (lateral) dunnage

Floor dunnage is used for the following tasks:

Dissipating and localizing sweat and moisture

Protecting the load from moisture and dampness on moist or wet stowage surfaces or stowage spaces

Dissipating or restraining moisture leaking out of the load, to protect other packages or the cargo transport unit

Protecting the load from soiling, contamination or mechanical damage from the stowage surface or stowage spaces

Protecting the cargo transport unit against negative influences from the goods

Floor dunnage protects moisture-sensitive cargoes, such as bagged cargo (e.g. coffee, cocoa) or bales (e.g. tobacco, tea) from sweat, which forms on a ship's sides and runs off over the decks. The floor dunnage "lifts" the cargo off the deck, so that water is able to flow off without coming into contact with the cargo. In the case of very sensitive cargoes, the space between cargo and deck has to be enlarged, or at least great care must be taken to ensure that the cargo does not under any circumstances come into contact with the deck over which sweat may flow. This is achieved by a double layer of dunnage or criss-cross dunnage.

Side dunnage (such as spar ceiling) has similar functions to floor dunnage:

Protection against damp or moisture penetrating from the side as a result of sweat or leakage from other cargo, but also protection of other cargo or of the means of transport against liquids escaping from the side of a load.

Protection against soiling and contamination on the sides, both of a single load against other loads or from parts of the means of transport, or protecting the latter against a specific load.

Protection against mechanical damage or other damage, such as chafing, tearing, chemical reactions, etc. both with regard to specific cargo and to other cargoes or parts of the means of transport.

Most general cargo ships have spar ceilings. These are wooden laths connected securely to the ship, which prevents direct contact between the cargo and the ship's side and allows the sweat to flow downwards over the steel ship's side. Sweat may form in particularly large amounts in holds under the water line during voyages from hot to cold climates.

To protect against damp or moisture or harmful dust penetrating from the sides, watertight and dust-tight materials such as plastic sheeting, oiled paper, and tarpaulins are to be used. Under certain conditions, canvas and mats should also be used, but never wrappers or paper. Sweat formation always occurs when temperature differences are too high, either with a positive temperature difference on the load or a negative temperature difference on components of the means of transport. Practical experience shows that wooden dunnage boards, wooden boards, mats, etc. provide good protection against mechanical damage. Whether or not it is necessary to use additional materials depends on the particular circumstances. Top dunnage is laid to prevent the consequences of leakage, sweat formation, bad weather, vertical shipping loads etc., which could damage a particular cargo or the cargo transport unit and its components. The main functions of the top dunnage are:

Protection against damp or moisture (sweat dripping from the deck, in particular, the weather deck)

Protection against dust or substances which threaten contamination or chemical reactions, (dust, cargo residues, hydraulic oil, etc.)

Protection against mechanical damage anticipated to arise from above or acting in an upward direction

All previously described materials can be used as top dunnage materials.

To protect against damp or moisture penetrating from the top, or to prevent moisture from being allowed to permeate upward, plastic sheeting, oiled paper, tarpaulins, and other watertight materials have proved themselves in practice.

This type of nonwoven fabric can absorb relatively large quantities of dripping water. Since the weight increases when these properties are used, it must be attached carefully.

The hygroscopicity of the generally sensitive goods means that top dunnage must allow a minimum of air circulation and evaporation. For this reason, air-permeable materials are used, such as paper, rice or bamboo matting, and jute coverings.

Interlayer dunnage variously has the functions of floor dunnage, side dunnage, or top dunnage, depending on how it is arranged. It is laid between two different batches or individual goods in a batch or load type.

Interlayer dunnage may fulfill two functions:

Protection of an underlying cargo from contamination by top cargo

Segregation of individual batches of cargo.

In some cases, it simultaneously helps secure the load by increasing friction, improving the distribution of load forces, or improving the stability of the load. All materials which have been described can be used. In addition, powdery substances such as talcum powder are introduced in the form of an intermediate layer or are sprinkled between layers, to prevent loads from sticking together, e.g. with bales of raw rubber. Interlayer dunnage comprised of mats provides adequate firmness and protects against mechanical damage.

Container dunnage: Standard containers are constructed so as to be spray-tight. For this reason, they do not have water drainage holes, since they would impair tightness. As the sweat has no way of draining way, as it does in a general cargo ship via wells and bilges, wooden dunnage is not very appropriate for use in standard containers. Floor and side dunnage is used to protect the cargo from contamination. Top dunnage has become increasingly significant in containers. Since a standard container cannot be ventilated, humidity levels become very high inside a container. Hot air rises upwards and moisture contained in the air condenses on the underside of the container ceiling during the night (cooling of the external air) or in transit from hot to cold climes.

Old dunnage may be disposed of along with the bottom cargo discharge in understanding with the stevedores or as per MARPOL.

dirty dunnage may taint or contaminate the next cargo

The dunnage materials must be clean and not dirty or greasy, else it may taint the cargo or spoil it.

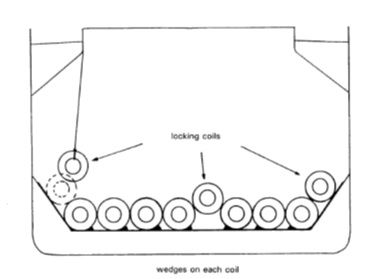

SPAR ceilings are wooden boards fitted on ship side frames to prevent breakbulk cargo coming in direct contact with shipside, and preventing any damage due to ship sweat.

The bilges must be clean/ dry and not foul smelling which may contaminate the cargo.

The one way bilge suction valve must be tested prior to each loading and the same logged.

The bilge covers must be covered by jute( burlap) cloth, so the cargo may not fall in bilges, thus blocking it, at the same time allowing any water content to seep through which may be pumped out.

Any ballast lines or tanks must be leak-free else may become a source of waterlogging in dry cargo holds.

If any foul or strong smell from the holds or bilges, branded deodorants may be used.

Comentarios