Securing cargoes (Dry Cargoes)

- Marine Teacher

- May 21, 2020

- 4 min read

Securing cargoes

Lashing Code(CSS: CODE OF SAFE PRACTICE FOR CARGO STOWAGE AND SECURING) Applies to all ships carrying cargo, other than wet cargoes, bulk cargoes, or timber deck cargoes. Which specifies the standards and methods of lashing all cargoes which are in particular liable to shift and result in damage.

Cargo Securing Manual ( CSM)

all ships to have onboard a “ Cargo Securing Manual”, which should be ship-specific and approved by administration or by class on behalf of the administration.

CSM will have the inventory of all lashing equipment on board, its location, the person responsible for maintenance of the same.

It would also illustrate methods of lashing various cargoes which may be carried on board.

All cargoes must be properly and solidly stowed and lashed, if not then during voyage it may shift resulting in damage. There should not be any play in the lashing and the tightening of wires must be monitored all the voyage.

Some cargoes like steel rails should be stowed fore and aft in order to prevent shipside damaged during rolling.

Various methods of blocking

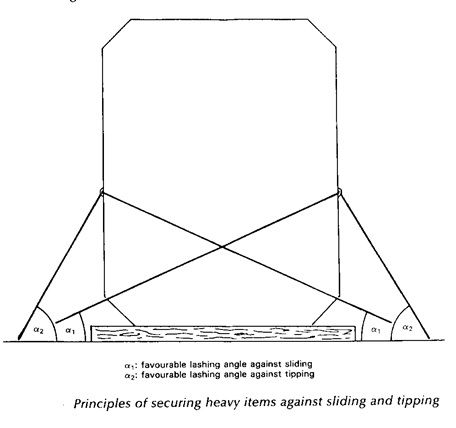

Methods of securing heavy loads

·

Attachment of Lashings to Heavy Cargo Items

If lashings are to be attached to securing points on the item, these securing points should be of adequate strength and clearly marked. It should be borne in mind that securing points designed for road or rail transport may not be suitable for securing the items on board ship.

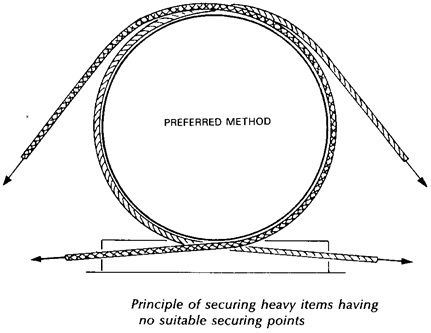

Lashings attached to items without securing points should pass around the item or a rigid part thereof, and both ends of the lashing should be secured to the same side of the unit.

Securing devices should be assembled so that each component is of equal strength.

Particular attention should be paid to the correct use of wire, grips, and clips. The saddle portion of the clip should be applied to the live load segment and the U‑bolt to the dead or shortened end segment.

Mixed securing arrangements of devices with different strength and elongation characteristics should be avoided

Various methods of stowing and securing vehicles and trailers

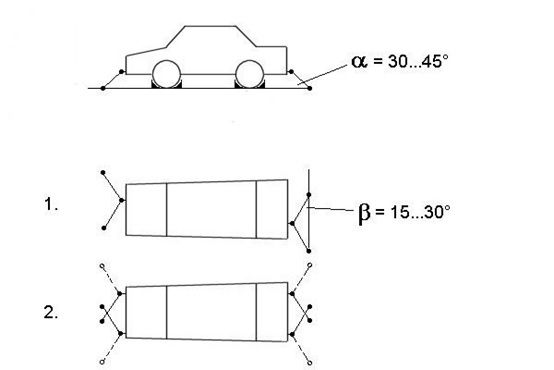

The manufacturer's loading instructions must be complied with. Cargo securing is basically dependent upon the available securing means, the weight and type of vehicle, and where it is stowed. The means of transport must be equipped for lashing vehicles correctly (lashings, lashing points, such as lashing rings and lashing pots and the like). When lashing belts are used, care must be taken to ensure that the same numbers of lashing belts are used at both front and rear. If no specific loading instructions are available, such lashings are attached to special lashing rings (see fig 1) or to the vehicle's towing gear. If no or insufficient lashing rings are available, the lashings may be attached to the springs, axles, and, under certain circumstances, to the chassis or vehicle frame. Lashings must not, however, be fixed to wheels, rims, or bumpers.

Cargo securing examples: Ro-Ro ship, special Ro-Ro ship (car carrier): Use lashing belts (e.g. special automobile lashing belts with lever ratchet tensioners) to absorb horizontal forces in order to avoid slippage and tipping. In maritime transport, lashing belts should be tight, but not highly prestressed. The vehicles are generally secured with 2 lashing belts to the front and 2 to the rear (see Fig. 2).

On inclined surfaces (ramps) and in the case of stowage athwartships, wheel chocks are additionally used and the number of front and rear lashing belts on the must should be increased appropriately (see Fig. 3).

Conventional ship or container:

Use lashing belts together with wheel chocks; in the case of stowage athwartships and on inclined surfaces, the number of front and rear lashing belts on the vehicle must be increased appropriately. In maritime transport, lashing belts should be tight, but not highly pre-stressed.

Figure 1: A webbing tape is fixed to the vehicle towing eye so that there are no problems in attaching two automobile lashing belts.

Figure 2: Automobiles secured onboard a ro-ro ship.

Figure 3: Automobiles secured onboard a ro-ro ship.

Figure 4: Load securing with wheel chocks and three-point lashing belt on a double-decker vehicle.

Bình luận