Ventilation and control of sweat (Dry Cargo)

- Marine Teacher

- May 22, 2020

- 9 min read

Updated: May 28, 2020

Cargo Ventilation

Speaking generally, bulk cargoes are ventilated to prevent the formation of cargo sweat or ship’s sweat which could damage the cargo, reduce the harmful heating of cargo, and/or remove hazardous gases from the cargo spaces. Ventilation in the wrong circumstances can do considerable harm and before a decision is made to ventilate a space it is necessary to consider the requirements of the cargo, the temperature, and humidity within the holds and outside and the presence or absence of sea spray. The types and positions of ventilators with which the ship is provided must also be taken into account.

Hold ventilators:

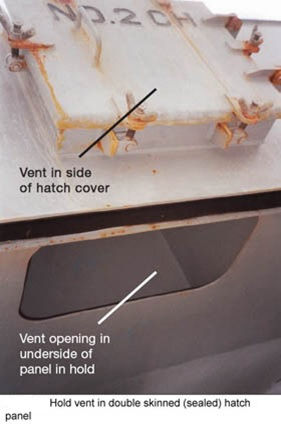

Most bulk carriers built since 2000 are provided with two hold ventilators set into the forward end of the hatch covers and a similar pair of ventilators set into the after the end of the hatch covers. (Figs. 15.1) These are easy to open or close, easy to clean, cheap to fit and maintain but are more exposed to seawater and spray on deck than are mushroom ventilators, and therefore require more attention. Ventilators of this type do not contain fans. The arrangements within the hatch cover depend upon whether the hatch panels are single (Fig. 15.2) or double (Fig. 15.3) skinned.

Older bulk carrier and any bulk carriers fitted with mechanical ventilation are more likely to be provided with two or four ventilation trunks per hold, with one or two situated at the fore end of the hold, and one or two at the after the end.

To avoid passing through the topside tanks these ventilator trunks are situated close to the ship’s centreline. Within the hold each such trunk often terminates in a simple square, round or rectangular opening in the deckhead (Fig. 15.4). Alternatively trunking may continue down the bulkhead, with slots at intervals to admit air to the hold at various levels. Portable plates can be put in place to close the lower slots when ventilation at lower levels in the cargo is not wanted.

Above deck the ventilation trunks may stand alone, each fitted with a mushroom cowl which gives some protection from spray and from the direct force of any wind (Fig. 15.5 and 25.6), or they may be built into the structures of the masthouses with openings situated in the masthouse sides, the masthouse top (Fig. 6.1), or at the masthead (Fig. 6.3).

Every ventilator must be provided with a means of closing so that all ventilation can be stopped in the event of fire. The means of closing may be in the form of a ventilator flap (or ‘damper’) set within the vent trunk (Fig. 6.3) and operated by an external lever, or a watertight door (Fig. 6.1), or may consist of a cowl which can be screwed down into a closed position by the operation of a valve wheel (Fig. 6.2 and 15.5).

Some bulk carriers are provided with ventilator fans set in the trunks of ventilators. When fans are provided they are normally fitted in the ventilator or ventilators at one end of the hold. Ventilator fans can usually be run in both directions so that they can be used either to deliver air to the hold or to draw air from the hold.

It may be possible to vary the speed of the fans, selecting full speed or half speed or a larger range of options. Ventilation assisted by fans is known as mechanical or forced draught ventilation, whilst ventilation which occurs as a result of the natural movement of air is called natural ventilation. Natural ventilation can occur as a result of a wind blowing, the ship’s motion, or the circulation of air resulting from temperature differences.

The Regina Oldendorff is provided with one ventilator at each end of each hold.

These ventilators pass vertically through the masthouses with the forward ventilator in each hold being on the starboard side and the after ventilator on the port side. The ventilators terminate on top of the masthouses with grilles which face aft and are provided with watertight doors (Fig. 6.1). No fans are provided, so any ventilation is natural.

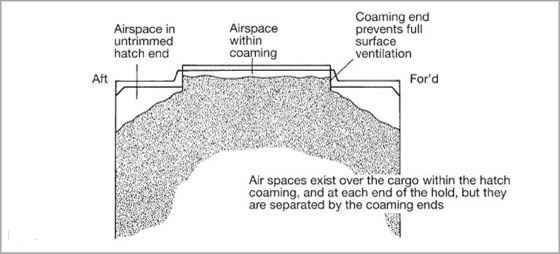

Some older vessels are provided with ventilators of the hinged-door typeset into the hatch covers, or with portable ventilator cowls, in addition to the mushroom or cowl ventilators at the extremities of the hold. Such additional ventilators are required to provide surface ventilation within the hatch square when a ship is carrying a cargo which fills the hold to coaming level, thereby sealing off the hatch square from the rest of the compartment (Fig. 15.6). The portable ventilator cowls have to be bolted in position on the hatch covers when blank plates have been removed.

Reasons for ventilating bulk cargoes: A number of difficult cargoes have special ventilation requirements to prevent overheating or to remove dangerous gases.

In such cases Masters and officers should be guided by any instructions provided by owners, charterers, shippers and/or the IMSBC Code5.

In Chapter 19 the carriage of several typical cargoes is described and these provide a good illustration of the varied reasons for ventilating. Coal is ventilated to remove hazardous gases. With steel a major object is to avoid the formation of sweat, which would damage the cargo. Iron ore has no particular need for ventilation although it is desirable to maintain a dry and healthy atmosphere in the holds for access and to reduce corrosion.

When there is no special need to remove gases, the reason for ventilating is to remove moist air and replace it with drier air to discourage the formation of sweat.

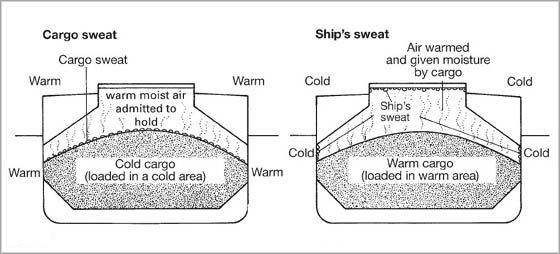

Sweat: Sweat is the name given by seamen to condensation which occurs in a ship’s cargo spaces. There are two types of sweat, ship’s sweat, and cargo sweat. For sweat to occur there must be moisture in the hold atmosphere and a difference of temperature between their in the hold and the cargo or the ship’s steelwork.

The temperature difference usually occurs as the ship moves from one climatic region to another or from a cold to a warm current or vice versa, and the larger the change in temperature the more likely is the formation of sweat.

Sources of moisture in cargo spaces: The most important source of moisture in a hold is the cargo. Most commodities, particularly materials of vegetable origin, possess some natural moisture and create an atmosphere, known as the storage atmosphere, in any compartment in which they are stored23. Moisture in a hold can also be the result of rainfall during loading and the air in a hold will be moist if conditions were moist when the hold was closed on completion of loading.

The amount of moisture in the air is measured by its dewpoint, which is the lowest temperature to which a mass of air can be reduced without condensation occurring. As condensation is a ‘bad thing’ it is helpful to remember that air with a high dewpoint is a ‘bad thing’. Dewpoint is obtained from a table, entered with readings taken from the wet and dry bulb hygrometer.

Cargo sweat: Cargo sweat consists of condensation which forms on the surface of cold cargo when warm moist air comes in contact with it (Fig. 15.7). Cargo sweat will form when the dewpoint of the air in the hold is higher than the temperature of the cargo. This is most likely to occur when the ship has loaded a cargo in a cold region and the air is admitted to the hold as the ship is traveling towards a warmer region.

To prevent cargo sweat when passing from a cold region to a warm region all ventilation should be stopped and the hold should be kept closed, with the air unchanged, as far as possible. The temperature of the cargo will only rise very slowly to equal the external atmosphere, and so long as the hold remains closed the air within it will gradually become warmer and able to hold more moisture.

With an inert cargo the dewpoint of the air in the non-ventilated hold remains constant as it warms up. If the cargo contains moisture it will give off moisture as it warms up. However, as the heat will flow from the shell of the ship into the hold atmosphere and from the hold atmosphere to the cargo, the temperature of the hold air stays a step ahead of the cargo temperature. Any moisture given off by the cargo can be held in the air.

It will be safe and desirable to ventilate only after the surface temperature of the cargo has risen to equal that of the air outside the hold or when the external air is exceptionally dry, so that its dewpoint is lower than the temperature of the cargo.

Ship’s sweat: Ship’s sweat is the condensation which occurs when warm moist air in the hold comes into contact with the cold steelwork which forms the deck and shell plating of the ship (Fig. 15.8). Ship’s sweat will form when the dewpoint of the air in the hold is higher than the temperature of the ship’s steelwork, conditions most likely to be met when the ship has loaded in a warm region and is steaming towards colder climates. Ship’s sweat caused by a low external air temperature is most likely to be deposited first in the vicinity of the hatch coaming and the fore and after ends of the hold amidships, as the topside tanks or double hull, even when empty, provide an insulating layer which delays the penetration of cold from the external air to the plating forming the tank/holds separation.

When a cold current is met, causing a low sea temperature, the side shell plating between the topside and lower hopper tanks will be cooled, providing conditions favourable for the formation of ship’s sweat in those areas.

When passing from a warm region to a cold region full ventilation should be continued whenever possible in order to withdraw moist air from the hold and replace it by drier external air. If the cargo contains moisture, the air in the hold will continue to be moist and will condense upon the ship’s cold steelwork unless it is continually extracted, and replaced by drier air.

General guidelines for ventilation: Ventilation should be stopped, by stopping fans when in use and closing the ventilators, when the vessel is shipping spray in the vicinity of ventilator intakes. Times of interruption of ventilation should be logged.

On short voyages in small ships such as minibulkers employed in the European middle trades it is normal to carry out no ventilation and to keep ventilators tightly sealed. With a low freeboard and regular rough weather the danger of shipping spray into open ventilators is usually found to be far greater than the potential benefits from ventilation.

On longer voyages if the cargo requires ventilation cargo holds should be ventilated when the dewpoint of the external air is lower than the dewpoint of the air in the hold. This will put drier air into the hold, forcing out wetter air and reducing the possibility of sweat forming. Dewpoint readings should be logged. However, dewpoint in the hold may be difficult to measure172. The hold may be full or unsafe to enter and when it is safe to enter any airflow will be the result of ventilation, meaning that the true temperature within the hold is not being measured. Another way of deciding when ventilation is needed for hygroscopic cargoes (agricultural cargoes such as grain, timber, animal feedstuffs and wood pulp that have a moisture content that can interact with air) is to use the three-degree rule.

The three-degree rule:172 says that a hygroscopic cargo should be ventilated when the temperature of the outside air is at least 3°C below that of the cargo temperature taken at loading. This rule avoids the need to take readings in the holds after the voyage has commenced and relies on the fact that the temperature of hygroscopic cargoes, except at their boundaries, changes very slowly during a voyage. However it should be noted that one authority (see Appendix 19.2) advises that the ventilation of grain cargoes is likely to do more harm than good.

Ventilation practice: When natural ventilation is being used with open ventilators at both forward and after ends, the air in the hold tends to travel from aft to forward. When forced ventilation is used it is normal to take advantage of this tendency and to drive the air from aft to forward.

Air forced into a hold by a fan will seek the shortest and easiest route through the hold. If the only route by which the air can leave the hold is through a ventilator at the far end of the hold, the air will tend to flow directly to that ventilator across the surface of the cargo. If an access hatch or other opening close to the inlet vent is left open, the air will leave the hold by the access hatch without traveling the length of the hold. This is known as ‘short cycling’ and is an inefficient form of ventilation. Short cycling should be prevented by ensuring that only ventilators are left open when the hold is closed.

When a hold is loaded with a bulk cargo the ventilation provided is usually surface ventilation, with air flowing over the surface of the cargo from ventilators at the after end of the hold to ventilators at the fore end of the hold or, in newer ships, from ventilators in the after end of the hatch covers to similar ventilators in the fore end of the hatch covers.

Ventilators situated at the hold ends can provide surface ventilation only for the nearby hold ends when the cargo is a low-density one topped up in the hatch square and preventing a flow of air from one end of the hold to the other. When the hold is filled the hatch square requires separate ventilation. (Fig. 15.6)

Through ventilation of a bulk cargo, when air is forced into the body of the cargo, is not normally required and is difficult to achieve. Some through ventilation can be provided aboard ships in which ventilator trunks extend to the bottom of the hold bulkheads. Through ventilation of coal is likely to cause heating and must be avoided.

The capacity of a ship’s hold ventilation fans is normally expressed in the number of air changes that can be achieved in an empty hold per hour. When a cargo is carried the number of air changes per hour will be increased, because the quantity of air which the hold contains is reduced.

Commentaires